Industry 4.0

- Home

- >

- Industry 4.0

Implementation of Industry 4.0

Aaran 1 is a mid-sized manufacturer of aerospace-grade machined components, supplying both domestic and export clients. The shop floor houses 60 CNC machines, which include high-precision turning and milling centers used for components with tight tolerances and demanding quality requirements.

Aaran 1 is operating three 8-hour shifts per day, running 24/7 to meet projected output and delivery timelines.

The Challenge Before The Leanworx Solution

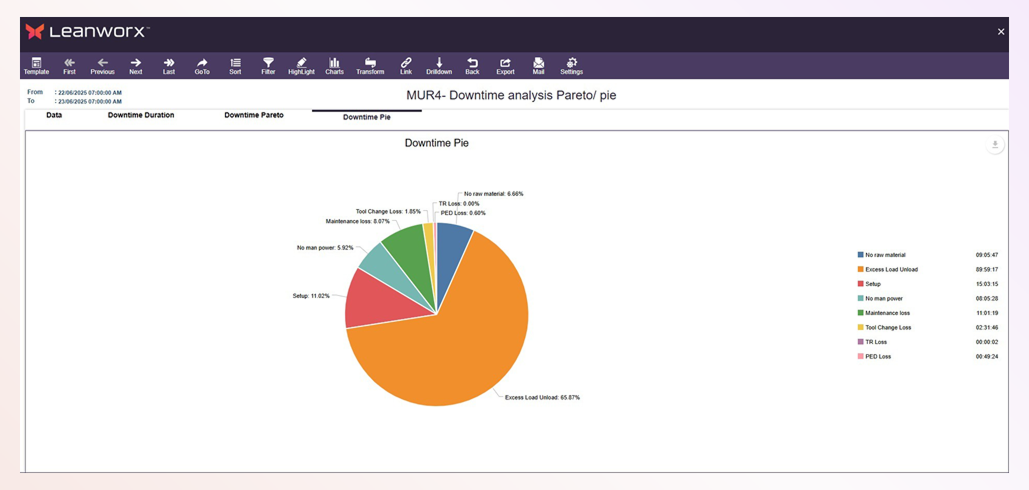

Real-Time Downtime Analysis and Spindle Utilization Tracking

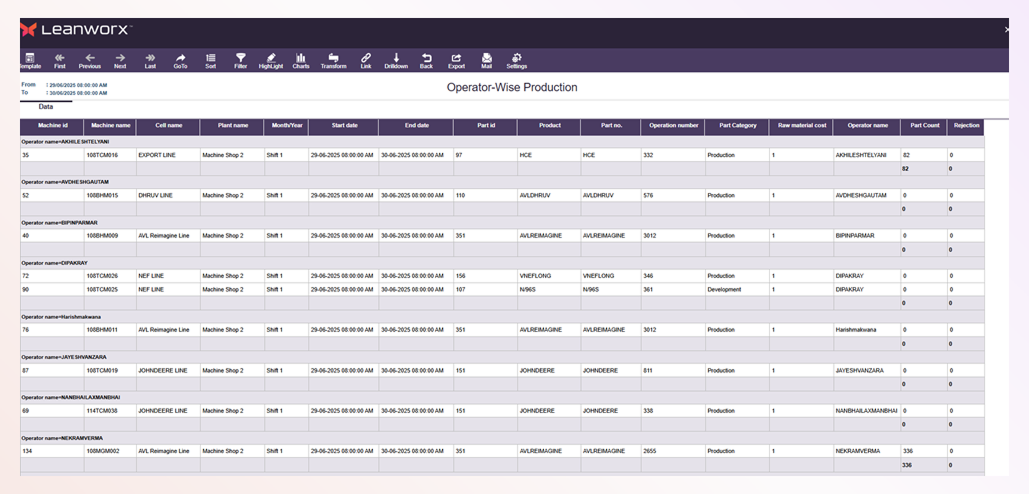

Leanworx was implemented across all 60 machines, capturing real-time machine signals including:

- Spindle on/off status

- Idle time

- Machine-level downtime reasons (automated + optional operator inputs)

- Shift-wise usage comparisons

Benefits:

- Track downtime minute by minute for every machine and shift

- Generate daily reports showing spindle utilization percentages

- Segment performance by shift, cell, and machine type

- Identify recurring downtime categories using Pareto charts

Leanworx reports became a part of daily operations:

Spindle Utilization

Spindle utilization charts

posted on the floor

Shift Comparisons

Shift-wise comparisons displayed weekly

Downtime Trends

Downtime Trends reviewed in weekly ops meetings

Pareto Charts

Pareto charts used to address recurring machine-level losses

To know more details about the Lean works please click on to http://www.leanworxcloud.com/