We’re here to help with all your inspection needs, whether you struggle with inspection capacity, or need extra capability, we can meet your requirements and alleviate the pressure. Our team has many years of experience in measurements and using CMMs and Optical Systems, We can supply on inspection reports as required

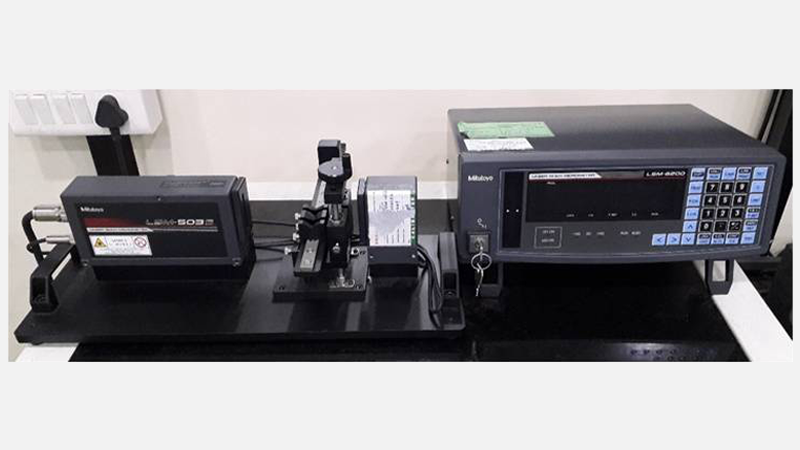

Please see our inspection equipment list for more information